working principle of rockwell hardness test|how to calculate rockwell hardness : importing Principle of Test. The Rockwell test consists of measuring the additional depth to which a carbide ball or Brale® diamond penetrator is forced by a heavy (major) load beyond the . 12 de fev. de 2024 · About This Software. RPG Maker VX Ace improves every aspect of RPG creation, making it not only the latest, but also the greatest engine in the RPG Maker Series. With multiple tileset support, .

{plog:ftitle_list}

Resultado da 5 de jun. de 2022 · A link to download R-User Games and yPER Studios’ free-to-play Spider-Man: Miles Morales Android can be found in the .

What is the Principle of the Rockwell Method? You can think of the Rockwell Hardness method as an impact-dependent hardness measuring method. The reason is that it requires an indenter with a known diameter and a specified load to impact the surface of the .The Rockwell Hardness Test uses a depth-differential method to test for hardness. .What is the principle of Rockwell hardness test? Rockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the indentation value, the harder is the .Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the .

Principle of Test. The Rockwell test consists of measuring the additional depth to which a carbide ball or Brale® diamond penetrator is forced by a heavy (major) load beyond the . The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation. The Rockwell hardness test involves making an indentation on the test material. The indenter is either a conical diamond or a steel ball. Indenter ball diameters range from 1/16 to 1/2 inches and are chosen based .Rockwell hardness testing is a useful and efficient way to determine the hardness of a material. It measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and .

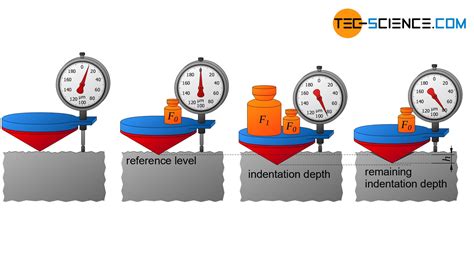

The Rockwell Hardness Test uses a depth-differential method to test for hardness. A predetermined minor load is applied to the test sample, and the depth measurement is taken. .The Rockwell hardness test, how does it work? Principle, application, hardness scales, minimum thickness, repeatability and error..The Rockwell method is a static hardness testing method, which can be further characterised as follows: It is one of the standardised procedures (ISO 6508, ASTM E18). The process is used to test hardness in the macro range (test . The residual indentation size of the indenter can be measured using optical measurement methods. Among the standardized optical hardness testing methods are the Brinell hardness test (ISO 6506, ASTM E10), the .

In the Rockwell hardness test, the measure of the hardness is not an indentation surface but an indentation depth. Either a carbide ball or a rounded diamond cone with a tip angle of 120° and a tip radius of 0.2 mm . ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for .

Principle of Rockwell hardness testing . The Rockwell hardness test is one of several common indentation hardness tests used today, other examples being the Brinell hardness test and Vickers hardness test. Most indentation hardness tests are a measure of the deformation that occurs when the material under test is penetrated with a specific type .What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared to other methods, like Vickers or Brinell hardness testing. Another advantage is the small area of indentation needed to carry out the .ACKNOWLEDGMENTS Theauthorwouldliketothankthefollowingpersonsforsharingtheir experienceandprovidinginformationforthisGuide.Theirinputandreview . This article discusses rockwell hardness testing, its applications and uses. . freelance writer with a bachelor’s degree in journalism from Buffalo State College and has 8 years of experience working in a professional laboratory. . details will be shared with OpenAI and retained for 30 days in accordance with their privacy principles.

Working Principles of Micro Hardness Testing. . Vickers, and eventually Rockwell hardness tests. Micro hardness testing still employs indentation to probe the surface of a sample and measure the resulting impression. The principles vary from test-to-test, but – typically – a sample is placed on a piezo-driven stage and positioned below a .The Rockwell method is a static hardness testing method, which can be further characterised as follows: It is one of the standardised procedures (ISO 6508, ASTM E18). The process is used to test hardness in the macro range (test force >= 49.03 N), more precisely with a test force of 29.42 to 1471 N. It is a differential-depth method.How Does Hardness Testing Work? The mechanism of hardness testing involves applying a standardized, rigid tool known as an indenter onto the material under examination. . For instance, in the Rockwell hardness test, hardness values range from 0 to 100 based on indentation depth, but each test method defines its scale uniquely.

The Rockwell hardness test is one of several common indentation hardness tests used today, other . “Dynamic Impact” is based on the Leeb principle of hardness,developed by Dietmar Leeb in the 1970’s. A spring loaded impact body is thrust to the test surface, effecting rebound. The speed of both the initialA standardized test procedure used to determine the hardenability of steel, the Jominy test (End Quench Test) can be performed using either the Vickers or Rockwell hardness test method. When selecting which to use, you should consider relevant standards, as well as the usual criteria when choosing between different types of hardness test.A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .

Variants on the Rockwell hardness test procedure are used depending on the material and strength of a part. The most common Rockwell variants include: HRC – Known as “Rockwell C,” a 150 kgf load is applied via a diamond in this method. Hardness generally refers to the resistance of a material to scratching or indentation, and a qualitative measure of the strength of the material. The most commonly used hardness tests are the Rockwell test, .3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually .The Rockwell hardness test. Rockwell is a fast hardness test method developed for production control, with a direct readout, mainly used for metallic materials. The Rockwell hardness (HR) is calculated by measuring the depth of an indent after an indenter has been forced into the specimen material at a given load.

Portable dried fruits and vegetables Moisture Meter distribute

12. Working Principle 1. SELECTING THE HEAD AND TEST BLOCK Hardened steel and hard alloys like Cast Iron were tested in the Rockwell C scale, using a diamond cone as head and a 150 kg major load. Brass was tested in B scale, using a 1/16” ball as head and a 100 kg major load. Copper was tested in F scale, using a 1/16” ball as head and 60 kg major load. The Rockwell hardness test is a measuring system used to determine how resistant a material is to another object. . it offers a practical and digestible introduction to working with a Rockwell hardness scale. . light and weighs only 1.2 kg. It is as accurate as desk testers and complies with the basic designing principles of Rockwell . Hardness testing is of immense importance for quality assurance in industry. Although the most widely used hardness test methods for metals—Rockwell, Brinell, and Vickers—were developed between 1900 and 1925, numerous technical innovations have been made in recent years, leading to an increase in productivity and the accuracy of hardness tests.

This article will first introduce the working principles, advantages, and limitations of the Rockwell and Vickers hardness tests, respectively. Next, we will focus on the in-depth discussion of the differences between each testing method. . Rockwell Hardness Test: Hardness is calculated by applying a load to the surface of the test material .The Rockwell hardness test is less affected by surface rough-ness compared to other methods such as the Vickers or Brinell tests. It can provide reliable hardness measurements even on . 2.3 Functional and Calculation Principle for Brinell Sample Surface Force (F) HBW = Brinell Hardness HBW = Constant x HBW = 0.102 x d 1= (Mean Indentation-Ø .

The most common types of hardness tests are: Rockwell Hardness Test: This test measures the depth of penetration of an indenter into the material. The Rockwell hardness test is the most commonly used hardness test in the industry due to its simplicity and accuracy. . Brake Master Cylinder – Detailed Working Principle; Introduction to . Consumables for the Vickers Hardness Testing System. The simplicity of the Vickers hardness tester allow for a relatively narrow choice of consumables and applicable spare parts. They include: The Indenter. A unique feature in the Vickers hardness test is the fact that every procedure always uses the same indenter.The Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials .Rockwell hardness testing is a method that determines the hardness of metals and polymers, and it is very common in most metallurgy and metal forging industry activities. Hardness testing does not test performance attributes. Yet, a material’s hardness correlates with its strength, wear resistance, and other properties. .

Looking into the features and functions of hardness testing machines, some key attributes have stood out from reviews and specifications from top industry websites. Rockwell Hardness Tester: It has an automatic load application system and accurate depth measurement for increased speed of testing and repeatability. One vital feature it has is .

rockwell hardness testing method

rockwell hardness tester least count

rockwell hardness test theory

VAZOU NA FAVELA 🌚🔥. NOVINHA DE 19 GRAVANDO TOMANDO BANHO 😱🔥 COMPLETO NO VIP 🔥 VAZADOS FAGRAS NOVINHAS LOMOTIF TRAIÇÃO LIVES TUDO ISSO EM 1 .

working principle of rockwell hardness test|how to calculate rockwell hardness